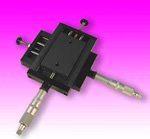

|

The

BSI

positioning

stage

represents

a new

approach

to stability

and

smoothness

for

both

scientific

and

manufacturing

applications. The

BSI

positioning

stage

represents

a new

approach

to stability

and

smoothness

for

both

scientific

and

manufacturing

applications.

Our

patented

linear

slide

combines

the

line

contact

advantages

of a

cross-roller

bearing

with

the

stability

and

damping

of the

pure

friction,

dovetail

design.

This

unique

approach

results

in a

stiffer

linear

bearing

structure

without

the

characteristic

high

coefficient

of

friction

of conventional

dovetail

and

square-way

slides.

Although

frictional

values

are

somewhat

higher

than

typical

rolling-element

slides,

the

BSI

stage

has

a clear

advantage

in relatively

low

duty-cycle,

micrometer-driven,

positioning

stage

applications.

The

BSI

stage

offers

a number

of important

features

and

performance

advantages:

- Physically

wider

than

many

similar

units

for

improved

cross-axis

stability.

-

Accuracy

on-axis:

.0001

in.

(2.5

microns),

full

travel.

- Level

cross-axis:

.0001

in

(2.5

microns).

- All

mounting

surfaces

flat

lapped.

- Stage

body

finish:

Black

anodized

aluminum.

- Stage

widths:

2

in.

(50

mm),

3

in.

and

5in.

- Stage

height:

0.75

in.

(metric

models:20mm).

- Full

travel,

double

spring-loaded

micrometer

or

fine-pitch

(100

tpi)

engagement.

- Positive

on-axis

manual

locking.

- Readily

stackable

in

X-Y

configuration.

- Base

adapter

plate

available

~

DIMENSIONS

&

PRICES

~

| SINGLE-AXIS

(X)

|

Model

No.

|

Work

Surface

(w)

|

Height

(h)

|

Length

(l)

|

Price |

SA-2-0.5 |

2

in

X

2.6in.

|

.75

in.

|

5.125

in.

|

Call |

SA-3-1.0 |

3

in

X

4in. |

.75

in.

|

7.600

in.

|

Call |

| TWO-AXIS

(X-Y)

|

Model

No.

|

Work

Surface

(w)

|

Height

(h)

|

Length

(l)

|

Price |

XY-2-0.5 |

2

in

X

2.6in.

|

1.5

in.

|

5.125

in.

|

Call |

XY-3-1.0 |

3

in

X

4in. |

1.5

in.

|

7.600

in.

|

Call |

| THREE-AXIS

(X-Y-Z)

|

Model

No.

|

Work

Surface

(w)

|

Height

(h)

|

Length

(l)

|

Price |

XYZ-2-0.5 |

2

in

X

2.6in.

|

6.437

in.

|

5.125

in.

|

Call |

XYZ-3-1.0 |

3

in

X

2.6in. |

6.437

in.

|

5.125

in.

|

Call |

|